Home

Shop

Tools

Empennage

Wings

Wings 2

Fuselage

Firewall

F-904 Bulkhead

F-705 Bulkhead

Aft Fuse Bulkheads

Fuselage 2

Fuselage 3

Fuselage 4

Fuselage 5

Fuselage 6

Panel

Firewall Forward

Canopy

Wiring

Engine

Miscellaneous

Fuselage

|

Date |

Description of Task | Hours |

| 12/12/06 | Placed order for the fuselage

kit. I am going with dual brakes, dual steps, electric

flaps and ailerons, and the sliding canopy. |

.5 |

| 1/10/07 | Received notification from Van's

today that my fuselage kit will be shipped the week of February

5th. |

|

| 2/23/07 | Received my fuselage kit today!

Two big boxes in perfect condition. Freight from Aurora,

OR was $333.00 (for those who wonder about these things). By the time Lynne got home I had the tops pried

off and we both got down to some serious inventorying. We

got all the major kits and odd parts inventoried and I will

tackle inventorying the sub-kits later. There was a lot of

packing paper! |

1.5 |

| 2/24/07 | Finished inventorying the

fuselage. I started organizing the various parts but can

foresee the day when I will spend an hour saying "I wonder where

I stashed those attach brackets". I am going to finish the flaps before starting on

the fuselage. |

2.5 |

| Firewall | ||

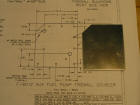

| 3/30/07 | The plans start by having you flute the

bulkheads but I will do this as I get to them. I decided

to begin laying out the firewall. I started by deburring

the sharp edges then I laid out the various support angles and

gussets. |

1.0 |

| 3/31/07 | It took a while but I finally found all the

firewall components (other than the pieces I will need to

fabricate).

I fabricated the F-601J angles, F-601P spacers and F-601E

stiffener and after clamping, back-drilled through the

pre-punched holes. I started with new drill bits and used

Boelube on every hole. |

3.0 |

| 4/2/07 | Clecoed the firewall recess and match-drilled.

Match-drilled the rest of the holes in the firewall using

generous amounts of BoeLube in each hole. |

1.0 |

| 4/4/07 | Finished fabricating and match-drilling the

F-601Z Fuel Pump Doubler to the firewall. |

1.0 |

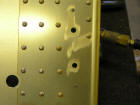

| 4/7/07 | Disassembled the firewall, dimpled the firewall

and recess, countersunk the stiffeners. Scuffed, washed,

Alumiprepped and Alodined the stiffeners and brackets.

Primed the stiffeners and brackets. Clecoed the assembly

together and started riveting. I started riveting the

bottom stiffener I could reach with the pneumatic squeezer. Riveted the F-601K recess and sealed with red RTV. This will help

keep oil and gas fumes out of the cabin. |

6.0 |

| 4/8/07 | Finished riveting the firewall. I clamped

the firewall vertically to a board which I clamped to my

workbench. This made riveting much easier. After

riveting one side, I "flipped" the firewall assembly over and

riveted the other side.  |

2.0 |

| F-904 (Center Section) Bulkhead | ||

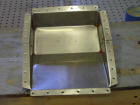

| 4/8/07 | Started fabricating the F-904 Center Section

bulkhead. I drilled the holes to 5/8" to receive the

SB625-7 snap bushings.

Next, I clecoed the F-904D center section aft sides to the

F-904B aft bulkhead. |

2.0 |

| 4/10/07 | Match-drilled the rivet holes in the F-904B and

F-904D (L&R). Clamped the F-904G's to the aft Center

Section and with spar bolts holding alignment, match-drilled the

upper and lower rivet holes. Took the assembly apart and

deburred. Ground a slight recess in each F-904D to provide

clearance for the snap bushings. Countersunk the F-904G's

on the forward side for the flush rivets. Riveted the edge

rivets that could be reached with the squeezer. Marked the location and drilled the 3/16" holes in the F-633 L&R

Control Column Mounts. |

1.5 |

| 4/13/07 | Finished riveting the F-904B and F-904D (L&R).

Riveted the F-904G's to the aft Center Section and agree with

several other builders that the -14 rivets called out are a

little too short. I realize the rivets are only there to

hold the bar in alignment until the main wing spars are

installed so I used the rivets provided. After the two

spar bolts are installed, those puppies aren't going anywhere. I then bolted the F-633 L&R Control Column Mounts to the Center section

and used my engineer's square to align. I clamped each

mount and back-drilled to 3/16's. Disassembled and trimmed

per the plans (Woohoo, I shaved off another 1.0004578 ozs!),

deburred and bolted and torqued (20-25 in/lbs). Note: I am being very diligent

in only using AN365-1032 nuts ONCE ONLY. If I ever have to

disassemble, I discard the used nut and replace with a new nut.

|

3.0 |

| 4/14/07 | I spent the longest time today just trying to

find the specific bolts for assembling the WD-610 Control

Column. Van's likes to package all bolts, washers and nuts

in "assortments". I decided to take the time and assort

them in the hopes this will save me time going forward. I

reamed all the holes and bolted the assembly together then took

it off.

I countersunk and installed platenuts on the top flanges of

F-904A/B. Installed the Cover Support Ribs, match-drilled

and drilled the snap bushing holes to full size.

Fabricated the F-904M Web Stiffeners and installed the

platenuts. I then installed the platenuts on the Cover

Support Ribs and riveted the ribs and stiffeners to F-904A. I fabricated the F-904J Center Section Spacers and bolted the

two center bulkhead assemblies together. I borrowed the

plywood spacer blocks from Ron Russ so I did not have to

fabricate them. |

6.5 |

| F-705 Bulkhead | ||

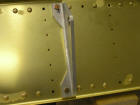

| 4/14/07 | I started the assembly of the F-705 bulkhead by

trimming the F-705B Center Section Bar and the F-605C Bar

Doubler. I fabricated the F-705H Spacers. |

1.5 |

| 4/15/07 | I spent a great deal of time in lining up the

F-705B Center Section Bar and F-605 Bar Doubler with the F-705A

Rear Spar Attach Bulkhead. I have read where many builders

had rushed this bulkhead assembly and later on discovered

minimum distance problems with the center section bar and rear

wing spar. I measured, checked, re-measured, clamped,

re-measured, adjusted, re-measured, re-clamped and

finally...drilled. This baby is dead-on.

I clecoed the F-705D Side Channels, Doublers and Top Channel.

I drilled the right seat belt anchors, clamped and match-drilled

the left anchors. I also trimmed the seat belt anchors

that would interfere with the floor ribs. I looked outside and was surprised to see the rain had turned

into snow! This is the latest date I have seen snow in

North Georgia. I will be off next week for Sun-N-Fun.

Ben Bierbaum and I will be flying a rented C-172K. |

4.0 |

| 4/21/07 | Had a great time at SnF. Hung out with

the EAA Chapter 1211 crew. Match-drilled the F-705. Disassembled the

assembly and deburred. |

1.0 |

| 4/27/07 | Fabricated the F-705J angle, F-705K plate and

the F-705L shim. Drilled in assembly with the F-705F

Channel, deburred and set aside for priming. Riveted the

platenuts to F-705D Bulkhead Side Channel and drilled the snap

bushing holes to full size.  |

4.0 |

| 4/28/07 | Washed, scuffed, Sanchem treated the F-705

parts then rattle-can primed the parts. Riveted the seat

adjustment supports to the F-705F Channel. Riveted the

entire assembly together.   |

4.0 |

| Aft Fuselage Bulkheads | ||

| 4/28/07 | Deburred, drilled snap bushing holes to full

size, riveted and primed F-706, F-707, F-708, F-709 and F-710

bulkheads.   |

7.0 |

| 4/29/07 | Fabricated the bellcrank support ribs and set

aside for priming. Fabricated the F-711 bulkhead and deburred

and set aside for priming. I fabricated the F-712 but

still need to finish match-drilling and deburring. My

bandsaw blade is shot so I will need to pick up another one.

There is a lot of cutting required! I pity those builders

who are trying to do all this with a hacksaw. I'm just

about ready for a major priming session. |

6.0 |

| 5/1/07 | Washed and scuffed the aft bulkhead parts. |

.5 |

| 5/4/07 | Primed all the aft bulkheads and various angle

and stiffeners. |

1.5 |

| Cinco de Mayo | I installed my new 18TPI bandsaw blade I got

from Tradesman Woodworking and trimmed the AL bars for F-711 and

primed. Assembled and riveted the F-706 bellcrank support,

F-710, F-711 and F-712. The F-712 required flush rivets on

the aft side where the vertical stabilizer will attach so I

countersunk and riveted.  |

4.0 |

|

Total Hours |

65.0 | |

| Next: Longerons |

Copyright ©2005-07

Hosted by NTI Networks