Home

Shop

Tools

Empennage

Wings

Fuselage

Panel

Veneering the Panel

Sealing the Panel

EFIS Tray Install

Back-Lighting the Panel

Installing Avionics Trays

Throttle Quadrant

Installed the Avionics

Firewall Forward

Canopy

Wiring

Engine

Miscellaneous

Avionics (Panel)

|

Date |

Description of Task | Hours |

| 2/22/08 | Placed my order for the wiring harnesses and trays

for my intercom, GPS/Com/Nav, Com2, transponder and autopilot from Tony at

Stark Avionics.

My final decision is now set:

|

|

| 2/26/08 | Ordered the EFIS wiring harness for the

Advanced Flight Systems

EF3500 from Tricia at AFS. |

|

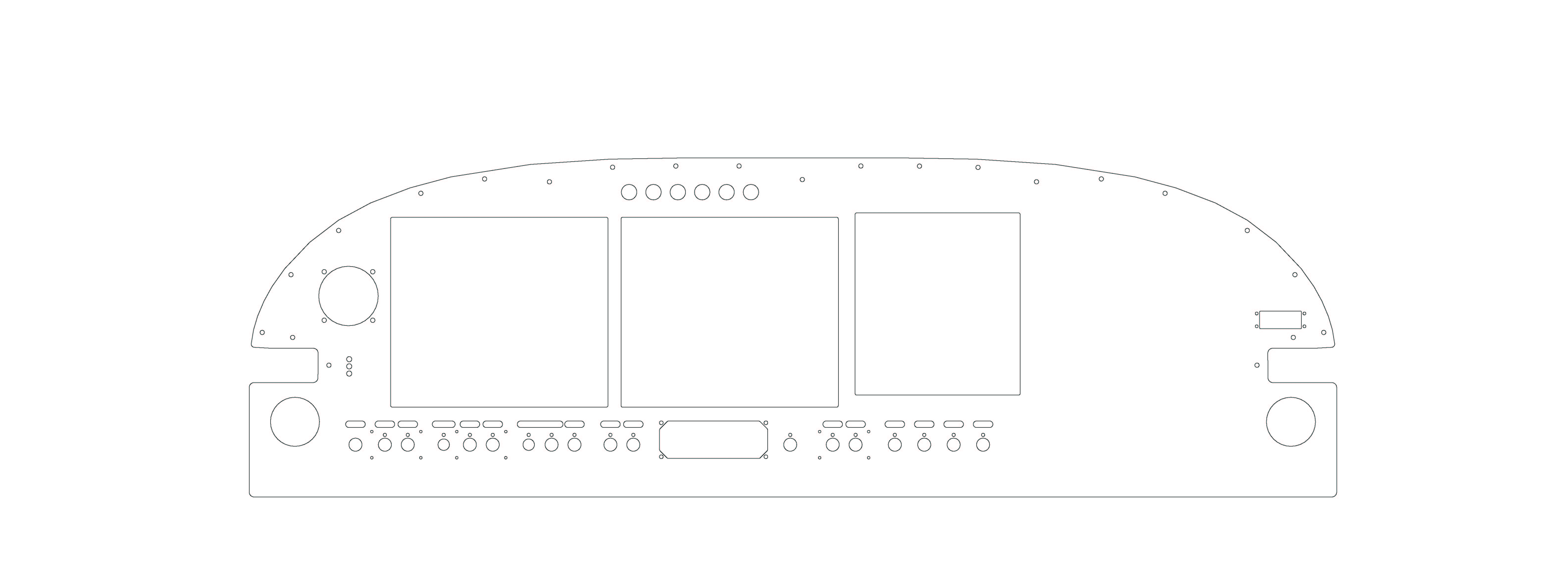

| 2/27/08 | Mike Behnke has been gracious enough to lay out

my panel design in TurboCad and has put up with my many,

many...., many design modifications. Here is an "almost

final" design. |

.5 |

| 3/2/08 | One thing I have learned in this project is to

never say "final" until the thing is flying. However,

today Mike and I collaborated on a "very close to final"

version. All we need to do is switch some switches around._small.jpg)

I also received my EFIS main wiring harness and OAT probe from

AFS. |

.5 |

| 3/10/08 | Today I received my switch guards I ordered from

Eric at Perihelion Design. |

|

| 3/12/08 | I received my avionics trays today from Tony at

Stark Avionics. I wanted the trays early so I could get

the exact measurements for the panel cut-out. |

|

| 4/26/08 | Ok, here is the absolute final version... Sorry

for the poor resolution. I sent the file to Jim Wright for

setup on his water-jet CNC cutting machine. He will be

cutting the panel out of .080" aluminum.

I am also sending off the CAD drawing for the switch panels to

Aircraft Engravers. They will cut and engrave the panels

for my rear lighting. |

|

| 5/22/08 | Today I received my switch labels from Wayne at

Aircraft Engravers

and they look great! I also expect to be receiving my

laser-cut panel from Jim by early next week. I will then

overlay the panel with the chestnut burl veneer, shoot it with

about 5-6 coats of clear urethane and then start installing the

switches and other components |

|

| 6/18/08 | Tonight I picked up my panel which was cut and

shipped by Jim Wright. It is absolutely beautiful. |

|

| 6/20/08 | Deburred the panel and test-fit some switches

and was pleased at the fit. |

1.0 |

| 6/21/08 | I had to enlarge the holes for the vents with

my Dremel tool. I then worked on the avionics trays

mounting. I purchased some "U-track" from a woodworking

supply house and will make my own adjustable tray mount. I

cut the track to length and drilled it for attachment to the

panel. I then fabricated the "floating" nuts out of .125"

angle and tapped them for 6-32 screws.

Next, I fabricated the F-793 angles that support the panel

outside the air vents. I then riveted the platenuts and

finally riveted the angles to the fuselage. |

4.0 |

| 6/28/08 |

Today I cut out the subpanel for the avionics trays. I

temporarily installed the panel blank and used a speed square

and a short ruler to extend the lines from the panel opening to

where the trays would hit the subpanel. After marking the

lines I used my Dremel tool with a cut-off wheel to cut out the

section. I then bent a 1/2" flange on the bottom for the

trays to ride on. After cleaning up the cut edges I have a

nice and tight opening. I finally received the SS 6-32x1" screws I needed to mount the avionics

trays to the panel. Tonight I veneered the panel.

Several months ago I found a couple of nice pieces of Chestnut

burl from

Certainly Wood.

These folks have the best selection of exotic wood veneers and

often have some rare species like the Chestnut burl. I was

not able to get the veneer in a wide enough piece to avoid

having to splice it. I used contact cement on the panel as

an adhesive and realized on the first attempt that I didn't have

enough adhesive to hold the burl flat. After totally

cleaning the panel I re-applied the cement and let it cure for

45 minutes. I then adhered the veneer using several

straight wires to hold the veneer off the panel until I had it

placed correctly. When veneering any burls you will have a high amount of "billowing" where the veneer expands and contracts with the contact cement. This is normal but requires quite a bit of patience to get the veneer to lay flat to the bonding surface. After getting the veneer bonded and reasonably "flat" on the

panel, I placed the entire panel in a vacuum press and set it to

cure. |

6.0 |

| 6/29/08 | I removed the panel from the vacuum

press and carefully routed out all the switch holes. |

3.0 |

| Sealing the Panel | ||

| 7/3/08 | I took today off work in order to get started

sealing the panel. I am coating the veneer with a

high-quality water-based urethane sealer. The goal is to

spray the panel, let dry (1.5-2.0 hours), then sand between each

coat with 400 grit sandpaper. Here it is after the second

coat.

I am using a $50 HVLP spray gun I picked up at Harbor Freight.

It does a really nice job. |

8.0 |

| 7/4/08 | Here is the panel after 7 coats.

While I was letting each coat dry, I went ahead

and worked on fitting and trimming the EFIS panel installation

trays. The AFS 4500 EFIS display units I am using are

designed to slide into the panel from the front. These

trays will help attach and stabilize the units. The issue

with my panel is the 0.5" flange around each tray interferes

with several surrounding components and requires trimming in

order to make it work. Here you can see how much I had to

trim. Also, because I have already veneered my panel, I decided to epoxy the trays to the back of the panel (as opposed to riveting). I verified this technique with Rob Hickman at AFS who agreed the T-88 epoxy would be more than sufficiently strong.

I also worked on wiring which is detailed

here. |

6.0 |

| 7/13/08 | Today I installed the

switch labels, switch guards and placards as well as the

switches and circuit breakers. I also installed my

annunciator lights.

The slots I had cut in the panel for the rear lighting had the

adhesive from the placards showing and with my luck, a bunch of

bugs will get stuck here and block the light. So, I filled

the slots with E6000 clear epoxy. With everything else installed I epoxied the EFIS trays to

the back of the panel. |

4.0 |

|

Back-Lighting the Panel |

||

| 7/21/08 |

I spent some time fabricating some polycarbonate "C" track that

I ordered from McMaster-Carr.

The track is just wide enough for the LED strip lights to nest for the

placard lighting. After getting the length right, I

sprayed the exterior of the tracks black in order to block the

light from escaping. Then I cut the light strips to the

appropriate length and soldered wiring leads to them as well as

connected them together in parallel. After adding heat

shrink, I epoxied the light strips inside the tracks using

E-6000. After the glue dried, I placed the tracks behind the placards

and marked their proper positions. I then epoxied strips

of "hook" side of some Velcro tape in strategic locations for

attachment. |

2.0 |

| 7/22/08 | Tonight I installed

the LED lighting strips to the rear of the panel and secured

with the "loop" side of the Velcro tape and powered the lights

to test. Perfect.

Here is the panel with the back-lit placard. It looks

really great in the dark...trust me. My only concern is

the light intensity may bee too bright. If so, I will add

a diode to reduce the voltage. I bought some nice DPDT indicator lamps from another RV

builder and used various color lenses based on the light

purpose. I printed the switch labels on clear Avery

mailing labels. I applied the labels to the annunciator

lights. I will wire them so by pushing the individual lamp

I can "test" them. This should not be a real issue since

they are LED lamps. |

1.0 |

|

Avionics Tray Install |

||

| 7/25/08 | Today I installed the

avionics trays for my panel. I fabricated a mounting

system using the "C" track I got from a woodworking store.

It would have been a LOT easier to have simply mounted the trays

using a couple of pieces of angle but this system will allow

greater flexibility should I ever change out avionics.

Next, I mounted the panel to the plane. Because the hole

in the subpanel was a little large at the top, I fabricated some

brackets from .075x.075 angle and mounted them in such a way

that they snugly hold the trays. Here you can see the

wires from the PMA8000B intercom. The trays were finally adjusted to be flush with the panel

face. Throttle Quadrant Installation I had to devise a way to mount the quadrant to the panel.

I used the idea from Bill Repucci

and make the mount using .075x.075 AL angle. Because the

quadrant will sit just below the flaps switch, I have to lower

it to avoid interference. I will need to design and make a

cover for the attachment angles. |

8.0 |

| 8/03/08 | I cut two pieces of

angle and riveted to the subpanel for support. I then

fabricated a length of angle and braced the entire structure to

the center rib. The pictures are a little hard to make out

but it is plenty solid.

I am really pleased to have this done. I also installed

the ELT remote module on the far right side of the panel.

I went ahead and removed the fuel selector valve and painted the

cover plate. I still need to install the final fuel line

from the selector to the firewall as well as the purge return

line. |

2.0 |

| 8/15/08 | Today I fabricated the

subpanel pieces out of AL angle. There will be three

pieces with the headset jacks on the extreme left and right and

a center section which will hold the purge valve knob as well as

the power point. I decided to just drill a hole in the

panel on the far right side for the heater knob. |

6.0 |

|

8/16/08 |

Installed the subpanel

pieces for the headset jacks as well as the purge valve and

power port. |

2.0 |

| 9/26/08 | Installed the TruTrak autopilot roll and pitch

servos and safety wired.

I also installed the AFS magnetometer and the 7.5aH auxiliary

battery. |

4.0 |

| 2/7/09 | Installed my avionics.

I also fabricated a tray for the GPS antennas. Here you

can see the antennas for the GNS430W, the AFS backup GPS, the

APRS GPS and the XM Satellite Radio antenna. |

2.0 |

|

Total Hours Panel |

Copyright ©2005-09

Hosted by NTI Networks