Home

Shop

Tools

Empennage

Horizontal Stabilizer

Vertical Stabilizer

Rudder

Empennage 2

Wings

Wings 2

Wings 3

Wings 4

Fuselage

Panel

Firewall Forward

Wiring

Engine

Miscellaneous

Empennage

|

Date |

Description of Task | Hours |

| 12/9/05 | Faxed order to Van's. | .2 |

| 12/21/05 | Received empennage and inventoried parts. I also organized the many small bags of rivets and assorted small parts. | 2.0 |

| 12/24/05 | My friend and flying partner Ben Bierbaum gave

me the Van's Toolkit practice project as a Christmas gift so

today my stepson Brandon and I put it together. When I saw

it on the website, I thought it was kinda cheap but I was amazed

how neat it was once I got to putting it together. It is

designed to require you to use many different skills as well as

a lot of different tools. I'm really pleased at how well

it turned out. It took about 4 hours.   |

|

| 12/25/05 |

Worked on the HS front and rear spars, fabricated the HS-908

brackets and the HS-909 shims. Prepped the ribs for

assembly. My step-son Brandon and my son Dustin check out the progress.  |

4.0 |

| 12/30/05 | Clecoed ribs to spars and drilled holes to #30. | 2.0 |

| 12/31/05 | Deburring, trimming plastic around rivet lines

on HS skins, clecoing right HS together in skin. Realized

I need more than 100 3/32" clecos...Ordered another 150 as well

as another 50 1/8" clecos.  |

6.0 |

| 1/2/06 | After talking with

Bill Repucci, I

disassembled the right HS and removed the blue plastic on the

inside. After doing so, I reassembled and it went together

much more easily. |

2.0 |

| 1/6/06 | I stopped by Ron Russ' house and bought some SanChem CC6100 from him and also borrowed some 3/32 clekos (Aircraft Technical Supply has them backordered). I also heard that Kyle Boatright, an EAA Tech Counselor, might fly over to Copperhill on Sunday so I needed to "step it up" so he would have more to see. | |

| 1/7/06 | Today I did the drill, deburr and dimple routine

on the right HS. It is amazing how tedious this is...

I decided to try out the Sanchem and ended up doing the entire

right HS. CC6100 is a non-chromate chemical conversion

(similar to Alodine, but non-toxic). It involves cleaning

the parts with Acetone first. The SanChem system is

three-parts: Part C is a cleaning solution. Clean

the parts and rinse with water. You then mix Parts A & B

in equal parts and wipe on. The "activated" aluminum turns

a bronze color almost immediately. After 60 seconds, rinse

and rivet. It adds no weight like conventional "paint"

primers and provides corrosion protection as good as Alodine.   |

10.5 |

| 1/8/06 | Picked up Kyle at the Copperhill (1A3) airport

around noon. I really appreciate the time our EAA Tech

Counselors donate to help out us newbie builders (hey, at least

we fed him). Kyle felt my drilling, deburring and dimpling

was impeccable. He also approved of the chemical

conversion coating. Thanks Kyle, see you again after I

pound a few rivets. But first, on to the Left HS and do it

all again.  |

1.0 |

| 1/9/06 | Clekoed together the Left Horizontal Stab. | 2.0 |

| 1/11/06 | Drilled skin to #40, disassembled left HS | 1.0 |

| 1/13/06 | Deburred all parts, countersunk spars and dimpled. Then I did the conversion coating. I switched from Acetone for pre-cleaning to MEK and am really pleased at the coverage. The MEK apparently cleans the aluminum better and allows better penetration of the SanChem. Time to rivet it together. | 6.0 |

| 1/14/06 | Began with the right HS. Riveted the spars

and doubler plates using the pneumatic squeezer. Riveted

the nose ribs and half of the forward spar to the skin.

The most difficult part to date has to be riveting the middle nose

rib, especially the first, forward-most rivet. I had to

drill out one rivet because it rolled but was careful and did

not enlarge the hole. The key here is to go slow and take

your time.     |

4.0 |

| 1/15/06 | Finished riveting the forward spar and the ribs on the right HS. I set the left HS in the cradles and clecoed the nose ribs for riveting. | 4.5 |

| 1/20/06 | Squeezed the nose ribs and feel they turned out

nearly perfect. I clecoed the front spar to the nose ribs

and the left HS skin and began riveting the skin to the front

spar. I also riveted the hinge brackets to the rear spar. |

2.0 |

| 1/21/06 | Finished riveting the skin to the front spar and

the skin to the ribs. Installed the rear spar and riveted

the skin using the pneumatic squeezer. It is amazing how

rigid the HS becomes when it is all riveted together. I

also assembled the VA-146 bearing and loosely bolted to to the

rear spar. I'll tighten it to spec later.

FINISHED THE HORIZONTAL STABILIZER. |

7.0 |

|

Total Hours |

54.2 |

Vertical Stabilizer

Rudder

|

Date |

Description of Task | Hours |

| 2/3/06 | I began by cutting the stiffeners for the right

rudder skin to their basic length and then cut the bevels on the

bandsaw. After final fitting to the skin I cleaned up the

saw cuts on the grinder and then match drilled the stiffeners to

the skin and clecoed.  |

2.0 |

| 2/5/06 | Match drilled the stiffeners to the right skin, took it apart and set aside. Cut the stiffeners for the left skin, smoothed the edges and match drilled. Deburred both skins and stiffeners. Dimpled both skins and stiffeners. Ready to sanchem. | 3.5 |

| 2/7/06 | Cleaned right stiffeners and skin with MEK, chemically treated. | 1.0 |

| 2/11/06 | I bought the Homebuilders Bolt/Nut/Washer Kit

from Aircraft Spruce. I over-torqued a bolt the other day

and needed to replace it...thought I might as well be prepared

for future screw-ups.

Cleaned left stiffeners and skin with MEK, chemically treated.

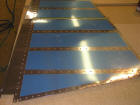

Several builders have asked about the SanChem conversion

treatment so I took a "before & after" shot. You can

really see the bronze conversion. I had planned to backrivet the stiffeners to the skins but my rivet tape order did not arrive. Instead I jumped ahead and assembled the rudder skeleton. Clecoed it all together and match drilled skins, then took it all apart. |

8.0 |

| 2/12/06 | Deburred all parts, dimpled the spar, ribs and skins. Countersunk the AEX wedge for the trailing edge. | 4.0 |

| 2/17/06 | I stopped by and saw a fellow RV-9A builder friend, Ron Russ, and borrowed his #10 dimple dies in order to dimple the counterweight rib for attaching the lead counterweight. It is really nice to have fellow builders nearby who are willing to loan the occasional tool now and then. I just couldn't justify buying a $36 set of dies for only two holes. (I found out that there are four additional holes that will require dimpling #10 on the fuselage). | |

| 2/18/06 | Took the rudder apart and SanChem treated all

rudder skeleton parts. I also received my order from Van's

of riveting tape and Proseal. I then back-riveted the

stiffeners to the skins.    Back-riveting is a piece of cake! I then riveted the skeleton

together. I found I was able to use my pneumatic squeezer

(w/3" yoke) for almost all the skeleton rivets except a couple.

There are a few places where I just used blind rivets. I

then clekoed the skins to the skeleton and started riveting.

I have decided to go ahead and purchase a 4" thin-nosed yoke in

order to squeeze the last few rivets in the top and bottom ribs

near the trailing edge so I will just leave them for now. |

8.0 |

| 2/19/06 | Finished riveting the last few skin rivets I can

reach with my squeezer. I clecoed the trailing edge

together to check for interference from any stiffeners or rivet

shop heads but it looks great. I am holding off on

riveting the trailing edge until I get a 4" thin-nose yoke and

finish squeezing the last few rivets.

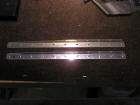

I bought a 4' piece of 2" x 2" x 0.25" angle to use in

back-riveting the trailing edge. I polished one side and

cleaned up with MEK. I also bought ProSeal from Van's and

a caulking gun with a small plunger to fit the tube. |

2.0 |

| 3/11/06 | Today, Jerry, one of the partners in my Warrier,

flew up to Copperhill (1A3)

to check out my progress. Jerry has just started building

an RV-9A and happens to have a 4" thin-nose yoke :). We

squeezed all but three rivets (the last three are in the

smallest section of the ribs) so I was thankful for his help.

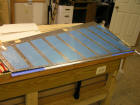

I attached the aluminum angle to the bench and match drilled the

rudder trailing edge. I took the time to layer masking

tape to the angle to ensure the angle was flush and level with

the table top. |

1.5 |

| 3/12/06 | Glued the trailing edge with T-88 and clamped to

the aluminum angle. I will give it a good week to set up. |

.5 |

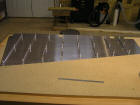

| 3/18/06 | Riveted rudder trailing edge. I took the

advice of several other builders and went nice and slow.

The result is a perfectly straight trailing edge.

I got Lynne to help me bend the leading edge and cleko. I

then match drilled, deburred and pop-riveted. I bought a cheap "Crowbar" at Home Depot, ground down the end

and finally riveted the last three rivets near the trailing

edge. I also made the insertion tool and installed the rod

end bearings. THE RUDDER IS FINISHED! |

4.0 |

|

Total Hours |

34.5 |

| Next: Empennage 2 | ||