Home

Shop

Tools

Empennage

Empennage 2

Right Elevator

Left Elevator

Trim Tab

Fiberglass Tips

Horizontal Stab Fairings

Wings

Wings 2

Wings 3

Wings 4

Fuselage

Panel

Firewall Forward

Wiring

Miscellaneous

Empennage 2

Left Elevator

Trim Tab

Fiberglass Tips

|

Date |

Description of Task | Hours |

| 6/3/06 | I've been notified my Wings will be shipped on

or about July 10th so I have decided to go ahead and delve into

the fiberglass and get this knocked out. I spent most of

the day sanding the rough edges and trial fitting the tips.

I will be installing nut plates on the vertical stabilizer tip

as well as the rudder bottom. Everything else will have

countersunk pulled rivets. I started with the rudder tip.

These I riveted with CS4-4 pulled rivets. The Vertical Stabilizer tip. I will be making a plug to

close the tip with some closed-cell foam I got from fellow EAA

1211 member and RV-4

builder Clay Smith. Next, the Rudder bottom. This required a special cut in

order to fit the fiberglass over the control arm. After

cutting a template out of cardboard and trial fitting, I

transferred the lines to the fiberglass. The Dremel tool

does a great job of cutting the fiberglass tips. I'm not really happy with how the fiberglass "bulges" around

the front spar and I will be checking with a few other builders

to see how they dealt with this problem. |

6.0 |

| 6/4/06 | Today I worked on the Elevator tips. After

trimming and sanding they fit pretty well. I made sure to

note to myself NOT to rivet these tips until I fit the empennage

to the fuselage and paint the elevators. They cover the

counterbalance lead weights which will need to be accessible.

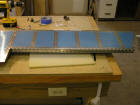

Next, I measured, marked, cut, (repeat) the Horizontal

Stabilizer tips. I'm pretty pleased with how these tips

look. Now all I need to do is fill in the tips which need glassing....

Otherwise known as the "fun" part. |

5.0 |

| 6/9/06 |

Cut foam pieces to plug fiberglass tips in HS and VS.

Epoxied in place with T-88.   |

1.0 |

| 6/11/06 |

Received my West epoxy and hardener. Glassed the foam in

the tips and then epoxied with a slurry of micro balloons.

Began the sanding process once cured. I'll need to epoxy

again and then sand to final surface coat. |

2.0 |

| 6/12/06 |

Gave the tips a second lay-up of epoxy and balloons. A

little sanding and I think they will do just fine. |

1.0 |

| 5/6/07 |

I decided to mount the delrin rudder stop I bought from

Jeff

Bordelon in

Round Rock, TX. This thing is so simple and elegant. |

.5

|

|

Horizontal Stab Fairings |

||

| 11/14/08 |

I re-installed the horizontal stabilizer and vertical stabilizer

and rudder in order to finish up some last details. I

started by trying a method of fiberglassing the HS ends which

are exposed. It has always bothered me to see RV's with

the holes in the ends of the HS. This would be a perfect

place for birds or wasps to build nests.

I cut a template out of styrofoam sheet and

after taping off the HS, laid up two layers of 12oz. glass with

the template mashing it in place. I am hoping to create a

"reverse" glass cover of

sorts. We'll see how it works. After the epoxy had set, I popped the cover off the styrofoam

template and laid up another fairing for the right HS. I also temporarily

installed the empennage fairing I got from

Fairings-Etc. |

2.0 |

| 11/15/08 |

I poured out some straight epoxy onto some sheet plastic and

laid the molded glass into the epoxy "bed" to try and get a

smooth outer surface. I also trimmed the flanges to .5". |

1.0 |

| 11/16/08 |

I mixed up some thickened micro and put a finish skim coat on

the left cover and set the right cover in the epoxy for setting. |

1.0 |

| 11/27/08 |

Riveted the cover fairings to the HS tips. |

1.0 |

| 11/30/08 |

Installed the LED taillight in the lower rudder fairing and ran

the wiring out. |

1.0

|

| 12/5/08 |

Began working to fit the empennage fairing. I used the

Dremel to sand away some epoxy overruns until it fit better.

I then drilled the fairing to the holes in the HS and Vertical

stabilizer. |

1.5 |

| 12/6/08 |

I drilled the fairing holes to #30 so I can tap the longeron and

install #8 screws. |

1.5 |

| Next: Wings | ||

| Total hours | 165.5 | |

|

Total Hours Empennage |

200.7 |