Home

Shop

Tools

Empennage

Wings

Wings 2

Left Wing

Gretz Pitot Install

Left Tank

TruTrak Roll Servo

Capacitive Senders

Closing Left Wing

Wings 3

Wings 4

Fuselage

Panel

Firewall Forward

Canopy

Wiring

Miscellaneous

Wings 2

|

Date |

Description of Task | Hours |

| Left Wing | ||

| 10/20/06 | Today I started by setting up the right wing on

the stand and clamped it down. I decided to build up the

left wing and then with it on the cradle I can work on the

ailerons and flaps for both wings simultaneously. Since

this is mostly a repeat of the steps with the right wing I will

not be posting as many pictures. I will have pictures of

new issues as they present.

|

1.0 |

| 10/21/06 | I drilled the spar to #40 for all the 124

platenut rivets as well as all the other flange rivets top and

bottom. Then I countersunk the rivets. I then dabbed the

countersinks with Alodine using a Q-tip. I began riveting

the #8 platenuts. I started countersinking the

platenut hole for the #8 screw. I used a cut-off #8 screw to gauge the countersink depth.

|

3.0 |

| 10/22/06 | Finished countersinking the spar for the #8

screws...all 62 of them. Alodined each countersink.

I also riveted the #6 platenuts for the inspection covers.

Drilled and riveted the two center section platenuts on the

spar. Drilled the tie-down bar to the spar and attached

the four platenuts and primed using the rattle can. Bolted

the tie-down and torqued to 25 in/lbs. Began working on the left wing rear spar.

Drilled and clecoed the W-907D and W-907E doubler plates to the

spar. Drilled the hole for the aileron pushrod using my

Unibit then cleaned it up with my Dremel tool. Took

the whole assembly apart and deburred the spar and doubler

plates. The rear spar is ready to chemically treat

with SanChem.

|

5.0 |

| 10/27/06 | Using the SanChem, I chemically treated the rear

spar and doubler plates. After drying, I countersunk the

holes in the rear spar where needed. I used alodine to

spot-treat the countersunk holes and riveted the rear spar

assembly. I saved myself

some time and just referenced

Smitty's website to determine which holes received rivets

and which shouldn't. Next, I placed the main spar and rear

spar on the table and clecoed the ribs to the spars. You

have to pay attention to the plans to arrange the ribs in the

proper orientation. I was really proud when I had finished

to find that I had NO left-over ribs :) |

3.0 |

| 10/29/06 | Match drilled the main ribs to the front and

rear spars. Disassembled the ribs and set aside for

chemical treating.

|

1.0 |

| 11/3/06 | Scotchbrite scrubbed all 15 main ribs with soap

and water.

|

2.5 |

| 11/4/06 | Etched and chemically treated the main ribs.

Clecoed the main ribs to the main spar and riveted.

Clecoed the rear spar to the main ribs and riveted. Drilled the 1"x1" angle to the outboard rib and attached. Hung the left wing assembly on the wing stand. Drilled the wing walk doubler as per the plans. Clecoed the inboard skin, doubler and outboard top skin to the wing skeleton.

|

6.5 |

| 11/5/06 | Match drilled the inboard and outboard skins to

the ribs.

Cut, deburred and drilled the J-stringers to the top skins.

Gretz Pitot Install

I am attempting to determine the best location for mounting my Gretz pitot. I basically have three options.

Option 1:

This is where Vans suggests installing the pitot and has

holes in the ribs to this bay for routing lines. I feel the

pitot head will be too close to the tie-down ring.

Option 2:

This location is one bay outboard of an inspection panel and

plenty far from the tie-down, but is located in the center

of the wing (inboard to outboard). Not sure if that really

matters.

Option 3:

This location is also one bay outboard of the 3rd inspection

panel and is the most outboard location. It will require

routing the pitot tubing around the bellcrank.

I have just

about ruled out Option 1 due to the close proximity of the

tie-down. Option 2 or Option 3 are still possibilities.

|

5.0 |

| 11/18/06 | Today my friend, Anton D'Allen came over to help

me out and proved to be a great helper. We started out by

match drilling the bottom skins.

After much debate I decided to go with Option 1. This

is the only option that avoids running the pitot tube and wiring

through the bellcrank area. I fabricated the attach angle

and drilled the bracket for riveting to the skin. I then

reattached the bottom skin and marked it for the pitot bracket

cutout. Cut the skin for the bracket and drilled for

rivets. I primed the pitot mounting tube and riveted the

platenuts. I will set the assembly aside until I rivet the

bottom skins. We clecoed the ribs in the leading edge assembly and mounted to the spar and clecoed. Fabricated the W-919 splice strip and drilled and clecoed with the W-908 rib. More Gretz Pitot install here. |

6.0 |

| 11/19/06 | Match drilled left wing leading edge. | 2.0 |

|

Total Hours |

35.0 | |

| Left Tank | ||

| 11/18/06 | I put the left tank skin in the cradle and clecoed the ribs.

I had to use my board and clamping technique in order to get the

clecos in but it worked. Next, I trimmed the T-911 and

T-911-INBD stiffeners, deburred and match drilled them to the

tank skin. Next, I carefully oriented the attach angles on the rear

baffle. Then, using the W-932DG drill guide, I drilled

each attach angle to #30. |

2.0 |

| 11/19/06 | Drilled attach angles to 3/16" for spar attach

and clecoed to tank baffle. Back-drilled attach brackets,

removed and deburred. Deburred tank baffle.

Re-attached baffle and clecoed to tank skin. Pop-riveted

the attach brackets to baffle. Installed tank to wing spar

and clecoed through spar with 3/16 clecos and through tank skin

to spar with 1/8 clecos. |

2.0 |

| 12/2/06 | Drilled the tank attach brackets through the

spar and then removed the tank from the spar. I had only

put one pop rivet in each bracket and as a result the brackets

moved as they were drilled. Sooo, off goes an order to

Vans for replacement brackets. I decided to go ahead and

order replacement elevator counterbalance weights since I seem

to have trimmed them to be too light. Started to

countersink the tank skin at the baffle attach. |

2.0 |

| 12/3/06 | Finished countersinking the baffle attach rivet

line. Drilled out the bad tank attach brackets.

Trimmed the T-410 reinforcement plates. |

2.0 |

| 12/9/06 | I'm still waiting for the replacement tank

attach brackets so on to other tasks. I deburred the

bottom skin ribs and began deburring the bottom skins.

TruTrak Roll Servo Bracket Installation |

5.0 |

| 12/10/06 | Deburred the left wing bottom skins, then

dimpled. |

3.0 |

| 12/21/06 | Disassembled and deburred the leading edge skin,

ribs and splice plate. Drilled the splice plate for rivets

and deburred. Dimpled the splice plate. Used a

reamer to enlarge the hole for the tie-down bolt to final size.

Set aside for priming. My replacement tank attach brackets finally arrived today so I'm back in business. I drilled the brackets and pop riveted to the tank (using two (2) rivets this time). After back drilling through the spar, I removed the tank from the spar and placed in the cradle. I removed the attach brackets from the baffle by drilling out the pop rivets. Drilled the attach brackets for K1000-3 platenuts. Countersunk the brackets and washed down with MEK. Set the brackets aside for priming. Fabricated the T-905 attach angle. I used the bench

grinder to finish trim the angle.

I match drilled the attach angle to the inboard rib and set

aside for priming. |

7.0 |

| 12/22/06 | Primed the tank attach brackets. Riveted

the platenuts to the attach brackets. Fabricated the T-410 reinforcement plates to the inboard and outboard ribs and test fit/ground down until the fit was perfect. Deburred and match drilled the T-410 reinforcement plates to the inboard and outboard ribs. I match drilled the capacitive sender plates to the second and sixth ribs per the plans. Drilled the 3/8" hole for the BNC connector in the inboard rib. Deburred, dimpled and riveted the platenuts in the capacitive plates. Used the fly cutter to cut the access hole in the inboard #1 rib. Match drilled the T-411 plate. Drilled the 3/8" holes in the inboard rib for the fuel vent fitting and the fuel vapor return fitting. Fit and drilled the T-406B fuel cap flange. Deburred and

countersunk the flange. I also fabricated the T-914 clip from a

scrap of .020. |

7.0 |

| 12/23/06 | Countersunk the T-407 stiffener ring for the

platenuts. Deburred and countersunk the T-407 and riveted the

platenuts. Drilled the hole for the fuel pick-up since the

T-411 plate did not have it pre-drilled. Fit and match drilled the VA-112 drain flange. Drilled the holes in ribs #2 and #3 for the fuel return line and deburred. Chemically treated leading edge ribs, splice plate, T-905 attach angle and T-411 cover plate. Disassembled tank and deburred stiffeners and ribs.

Deburred skin. Fabricated the small plate for covering the

tooling hole in the outboard rib. Drilled and deburred cover

plate. Scuffed skin along rib and stiffener line. |

6.0 |

| 12/26/06 | Dimpled leading edge and left tank skins.

Set up area and prosealed and riveted stiffeners, fuel flange, drain flange

and cover plate for tooling hole in outboard rib. I used

my new (used) pneumatic Semco dispensing gun for dispensing the

proseal and it worked great. Riveted the platenuts on the

splice plate. |

6.0 |

| 12/27/06 | Prosealed and riveted tank ribs #2-#6.

Drilled anti-rotation bracket to T-411 tank access cover plate. |

5.0 |

| 12/30/06 | Prosealed and riveted the inboard and outboard

ribs. Riveted the T-905 attach angle and the T-410

reinforcement plates.

Prosealed and riveted the anti-rotation bracket to T-411 tank

access cover plate. |

3.0 |

| 12/31/06 |

Capacitive

Sender Installation I wanted to detail the installation of the capacitive senders for the fellow builders who would like to see the details. I

started by loosely installing the inboard and outboard

capacitive plates. Then installed the BNC sender in the

inboard rib. I rough installed the vent tube and when I had the proper

length I flared the end and loosely installed to the AN-4

bulkhead fitting. Next, I crimped and then soldered the ring connectors on the

wire ends. I then twisted the 18 AWG wire around the vent tube to secure

the wire and remove the excess slack. Then I loosely

connected the connectors to the capacitive plates. Then I installed the plates permanently. Next, I installed the fuel vapor return line. Like the

right wing tank, I ran the return to the middle of the third

bay. Finally, I mixed up 4 oz. of proseal and coated the bulkhead

fittings of the vent tube and vapor return line and torqued to

55 in/lbs. Then I covered the entire fittings with

proseal. I also covered the ring connectors and connector

screws and nuts. I also prosealed the wire in places where

it could rub against the tank skin. |

7.0 |

| 1/1/07 | Prosealed along rivet lines and attached baffle

with clecos in every hole. Attached and prosealed tank

attach brackets. Riveted baffle to tank, riveted baffle to

rib flanges and riveted tank attach brackets to baffle/rib

flanges. |

4.0 |

| 1/5/07 | Mixed 2.0 oz of proseal and applied to the

inboard rib around the cover plate. Applied the cover

plate and, after swirling each screw in proseal, attached

permanently. Now to let the proseal cure for about a week

and test for leaks. LEFT

TANK DONE! |

.5 |

| 1/13/07 | Tested tank for leaks. NO LEAKS! |

.5 |

|

Total Hours |

62.0 | |

| Closing Left Wing | ||

| 1/6/07 | Deburred top outboard wing skin and began

dimpling. |

2.0 |

| 1/7/07 | Dimpled top outboard wing skin. Deburred

top inboard wing skin and the wing walk doubler and dimpled

both. Deburred J-stringers and dimpled. Began deburring

wing ribs and rear spar in preparation for dimpling. |

7.0 |

| 1/11/07 | Received notification from Van's

yesterday that my fuselage kit will be shipped the week of February

5th. I had better get moving to finish the wings. I

finished deburring the main wing ribs and rear spar and started

dimpling. |

1.0 |

| 1/12/07 | Finished dimpling main wing ribs and rear spar.

Used deburring tool to "ream" the dimples in the rear spar.

Now it's time to prime! |

2.0 |

| 1/13/07 | Chemically treated the leading edge skin.

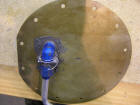

Polished one of my fuel tank caps. Several builders are

opting to buy the Van's "deluxe" fuel caps. I couldn't

justify spending an additional $100 per cap so I made my

own. I started by disassembling the cap. Next I

started sanding with 240 grit sandpaper. I progressed

through 320 grit, 400 grit, 600 grit and finally wet sanded with

1000 grit. All in all it took 30 minutes for the first

cap. |

3.0 |

| 1/14/07 | Began riveting the leading edge together. |

1.0 |

| 1/19/07 | I finished riveting the leading edge and placed

on the spar. I started riveting the leading edge to the

spar and riveted all that I could reach by myself. I began the

process of chemical treating the inside of the top skins as well

as the wing walk doubler and the J-stringers. Since it was

around 26º

outside and the water froze on contact with the skins, I was

only able to clean scuff the skins and chemically clean/etch the

skins. |

3.0 |

| 1/20/07 | Today my friend and fellow EAAer, Jim Olsen,

came over to help me rivet the top skins. I started by

chemically treating the inside of the skins and set them aside

to dry. Jim helped me by bucking the inside spar flanges

of the leading edge. We then used the pneumatic squeezer

to rivet the top and bottom to the spar flange. Next we mounted the fuel tank and bolted it to the spar. The bolts were torqued to 25 in/lbs. Next we screwed the tank top and bottom to the spar flange. I was pleased to see there was no gap between the leading edge and the tank. We then clecoed the inboard and outboard skins to the spars and ribs. My EAA Technical Counselor, Kyle Boatright, called as he was heading our way for a visit so we met him at Copperhill airport. Kyle had not seen the project since I had received the wing kit so he looked it over pretty well. I really like having Kyle looking over my shoulder not only because he has built an RV but because he is exceptionally knowledgeable in so many areas of aircraft construction. With Kyle's letter of approval, we returned him to the airport. After a great Mexican food lunch, Jim and I returned home and

riveted the top skins. Like the right wing, we

back-riveted the top skins and then riveted the J-stringers.

We then removed the wing from the stand and placed it in the

cradle. After Jim left, I finished riveting the skins to

the rear spar. |

8.0 |

|

Total Hours |

307.2 | |

| Next: Wings 3 |