Home

Shop

Tools

Empennage

Wings

Wings 2

Wings 3

Ailerons

Wings 4

Fuselage

Panel

Firewall Forward

Canopy

Wiring

Miscellaneous

Wings 3

| Ailerons | ||

|

Date |

Description of Task | Hours |

| 1/21/07 | From this point on I will be working on both

wings simultaneously. I began by clecoing the aileron

attach brackets to the rear spars and match drilling. I

then deburred each bracket and scuffed with scotchbrite pad and

soapy water. I decided to alodine the brackets as they are

easy to treat in a bath. After soaking for 2 minutes,

rinse with water and hang to dry.

After drying I reassembled and riveted to the rear spars.

I was able to squeeze all the rivets except the innermost one on

the outboard brackets. It was easy to rivet with the gun. Next I began working on the flap brackets. It took a

while to figure out the drawings in the plans as to how the flap

brackets attach to the rear spars. I made the 925-A and

925-C brackets and deburred. I was able to match drill and cleco three of the six flap

brackets. I will complete all six and check the alignment

before riveting. |

9.0 |

| 1/26/07 | Finished match drilling the remaining three flap

brackets and verified the alignment.

I clecoed the bottom skins on temporarily and match-drilled the

rivet holes around each flap attach bracket into the support

angles. |

3.0 |

| 1/27/07 | I then disassembled and deburred all the parts.

I alodined the parts and then primed with self-etching primer.

I riveted the flap brackets and support angles. I was able to

reach about half of the rivets with the pneumatic squeezer and

the rest had to be driven with the rivet gun. You can

easily tell which rivets were driven by the gun because they are

somewhat distorted and "silver" in color. Next, I began installing the aileron and flap gap fairings.

It is interesting to note that when the plans say "Drill, deburr

and dimple where required" that this means at least 4-5 hours of

work! I installed the fairings, clecoed and match-drilled.

After deburring I dimpled the #40 holes where it attaches to the

top skin and set the fairings aside for priming. I (FINALLY) started work on the ailerons by edge deburring the spars and the

A-908 reinforcing plates. After match-drilling, I

deburred, clecoed and match-drilled the A-904 nose ribs to

the spar. |

12.0 |

| 1/28/07 | I installed the counterbalance pipe and

match-drilled to the nose ribs. I marked the holes and

drilled the pipe on the bench press. I then was able to

cleco one hole per side and tape a rivet in the other holes in

order to hold it in place as I clecoed on the nose skin. I

then match-drilled the nose skin.

Next, I cut the A-910 stiffeners and deburred. I then

started deburring the aileron top and bottom skins. |

7.0 |

| 2/1/07 | Well, today we got snowed in and couldn't get

out to go to work...so I worked on the ailerons. I

finished deburring the skin edges and clecoed both ailerons

together and match-drilled. I noticed that on the top

skins that they are about 1/16" short. It seems that some

kits have this issue and it is acceptable so I am moving on.

I disassembled the left aileron and match-drilled the stiffeners

to the top and bottom skins. I deburred the stiffeners,

skins and countersunk the spar. I dimpled the left aileron

top and bottom skins and set aside for priming. |

4.0 |

| 2/2/07 | I received a call today from Vans that they

needed my CC in order to process the packaging of my fuselage

kit. It is still scheduled to ship the week of the 5th.

I expect to receive a call from Fed Ex Freight around Wednesday

or Thursday to schedule delivery on Friday (hopefully).

I'd better get busy. |

|

| 2/3/07 | More deburring. I disassembled the right

aileron and deburred the spar. I countersunk the spar and

deburred the other parts of the right aileron. The aileron

inboard and outboard ribs are too narrow at the aft ends to get

the pneumatic dimpler inside so I had to use my trick of using

the pop-rivet nail dimpler and some washers.

I drilled the lateral rivet holes in the counterbalance pipes.

These pipes are stainless steel so I drilled the #30 holes using

the drill press at low speed using some oil. |

3.0 |

| 2/9/07 | Well, it's Friday and no word yet from FedEx

Freight. I guess it will be next week...

Deburred the

right aileron top and bottom skins and then dimpled and set

aside for priming. Dimpled the inboard and outboard ribs

of the right aileron. Deburred the spar holes for the flap and aileron gap fairings

on both left and right wings. |

2.0 |

| 2/10/07 | Primed (chemical treated) flap and aileron gap

seals, left and right aileron spars, stiffeners, ribs and skins.

Riveted flap and aileron gap seals on right wing. |

7.0 |

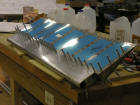

| 2/11/07 | Riveted flap and aileron gap seals on left wing.

Riveted stiffeners on aileron top and bottom skins.

Ready for aileron final assembly. |

4.0 |

| 2/17/07 | Assembled right aileron and drilled trailing

edge. Deburred trailing edge and dimpled.

Countersunk AEX wedge. Riveted spar, ribs and

counterbalance. Riveted top and bottom skins.

Clecoed trailing edge and AEX wedge with T-88. |

6.0 |

| 2/18/07 | Riveted trailing edge of right aileron.

Assembled left aileron and drilled trailing edge. Deburred

trailing edge and dimpled. Countersunk AEX wedge.

Riveted spar, ribs and counterbalance. Riveted majority of

top and bottom skins. I heard from ABF that my fuselage

should be delivered on Thursday! WooHoo! |

5.0 |

| 2/22/07 | Well, I confirmed delivery today and took the

day off work to meet the driver. I called fellow EAAer,

Jim Olsen, to come by and help me off-load and inventory.

Well, by 11:00am, when the delivery failed to show I called

Brown Cartage and they told me the driver forgot to load the

"packages" on the truck.... UNBELIEVABLE!!! They promised

to make the delivery Friday and I did not need to be here.

Oh well, might as well take advantage of a day off and work on

the plane. I finished riveting the skins to the spar as well

as the ribs. I then weighed the aileron to the table and

again used T-88 adhesive to lightly glue the AEX wedge and

clecoed every hole. I used clothes pins between every

cleco as well as a few clamps to ensure a tight trailing edge.

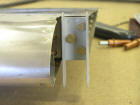

Now to let it set up before riveting. I scuffed the attach brackets and drilled to 3/8". I

bolted the brackets to the right aileron. |

2.0 |

| 2/24/07 | Riveted the trailing edge of the left aileron.

I drilled the aileron and attach brackets to 3/8" and reamed the

holes. I realized that somehow I had failed to rivet the last hole of the

leading edge to the spar. I decided to install a MK-319-BS

pop rivet. It should be more than adequate and

primer/paint will cover. Good enough. Bolted the attach brackets and torqued to 25

in./lbs. AILERONS FINISHED! |

2.0 |

|

Total Hours Ailerons |

44.0 | |

|

Total Hours Wings |

410.7 | |

| Next: Wings 4 |

Copyright ©2005-2007

Hosted by NTI Networks