Home

Shop

Tools

Empennage

Wings

Wings 2

Wings 3

Wings 4

Flaps

Pushrods

Riveting Bottom Skins

Gretz Pitot Install

Wing

Wiring

HID Light Install

Wingtip Hinge Install

Fuselage

Panel

Firewall Forward

Canopy

Wiring

Miscellaneous

Wings 4

| Flaps | ||

| 2/22/07 | I started by edge deburring the flap components

and clecoed the leading edge attachment assemblies. I then

match drilled and clecoed to the spars.  |

4.0 |

| 2/25/07 | Fabricated the 608A brackets as well as the 608C

spacer.

Clamped the bracket and spacer to the spar and back-drilled using the

spar holes as a guide.

The plans call fr drilling 5/8" holes in the top of your table and

since I didn't want to do that, I decided to build a

"sacrificial" table top. I ripped a 12" x 8' piece of

plywood and built a frame out of 2x4's and 1x4's. After

securing the top to the frame I have a top that I can throw away

once the flaps are complete.

I clecoed the bottom skin to the left flap spar and then drilled

through the bottom skin into the top of the sacrificial table. |

|

| 3/3/07 | I removed the flap skin and drilled out the

cleco holes to 1/2" so the clecos will fall below the table

allowing the skin to lay flat.

I assembled the left flap by clecoing the ribs to the spar,

skins to ribs and leading edge skin to spar. I weighed the

flap assembly down with some threaded rods I had laying around.

I taped them together and each bundle weighed approximately 5

lbs. each. Inserted

trailing edge AEX wedge and drilled trailing edge. Match

drilled all holes. Disassembled flap components and deburred. Drilled K1000-4

platenut to inboard rib and bracket and countersunk. |

10.0 |

| 3/4/07 | Deburred top left flap skin. Assembled

right flap by clecoing ribs to spar,

skins to ribs and leading edge skin to spar. Inserted

trailing edge AEX wedge and drilled trailing edge. Match

drilled all holes except inboard flap attach bracket.

I decided to print out some true size photos of the avionics I

plan to use and start a "mock up" panel. Over the next few

months I will be able to look at it and see how it fits. |

4.0 |

| 3/9/07 | Drilled inboard flap attach

bracket and drilled platenut. Disassembled right flap

assembly and deburred leading edge ribs and main ribs, leading

edge skin and spar. |

2.0 |

| 3/10/07 | Countersunk spar and trailing

edge AEX wedge. Deburred left and right flap skins and

dimpled. Dimpled ribs. Scuffed left flap ribs and

leading edge components with dishwashing liquid. |

6.0 |

| 3/11/07 | Scuffed right flap components

with dishwashing liquid. |

1.0 |

| 3/13/07 | Alodined ribs and flap bracket

components. Sanchemed spars and AEX wedges. |

1.5 |

| 3/14/07 | Scuffed top and bottom skins for

both flaps with soapy water. Dimpled leading edge skins

for left flap. |

1.0 |

| 3/17/07 | Finished priming the flap

components. I decided to alodine the ribs and leading edge

hinge brackets and then sprayed with self-etching primer.

I used SanChem for the inside skins and leading edge skins. |

3.0 |

| 3/18/07 | Riveted the leading edge brackets

for both flaps and riveted them to the spars. Riveted the

remaining ribs to the spars.

Clecoed the top skin and leading edge skin to the

left flap and riveted. Flipped the left flap over devised a way to

weigh down the skins. I found some 1x10's and clamped them

to the table. It works really well. I then clecoed the bottom skin and started

riveting the bottom skin and leading edge skins to the spar. |

7.0 |

| 3/21/07 | Finished riveting the bottom skin and leading

edge skins to the spar. BTW, I used -4 length rivets

because I didn't seem to get large enough heads using the -3.5's

called out in the plans. I then drilled the bottom skin to

the ribs to 7/16 and installed the blind rivets. |

2.0 |

| 3/22/07 | I decided to use proseal on the trailing edge

AEX wedge. I mixed about 2.2 ozs. per my scale and applied

a thin coat to both sides. After inserting the wedge I

clecoed every hole and left to set up.

I clecoed the top skin and leading edge skins to the spar and

ribs of the right flap. I worked on the left wing aileron bellcrank by reaming the

brass bushing for the bolt. I also had to ream the

bellcrank in order for the bushing to turn smoothly. I

decided that "my favorite grease" (inside joke) is Aeroshell 33.

I greased the bushings in both bellcranks and installed. I'm ready to construct my aileron pushrods but need to verify

that the pushrod lengths specified in the plans is correct. |

3.0 |

| 3/23/07 | I called Van's Technical Support and was told

the lengths specified in the plans are correct. Cut the

W-917 stick to aileron bellcrank pushrods 90 17/32".

After

deburring I taped one end of each tube and mixed up some primer.

For this purpose I am using Nason 2-part self-etching epoxy primer.

I poured the primer inside each tube and coated the inside

thoroughly. I also primed the inside of the W-918 aileron

bellcrank to aileron pushrod. Finally, I used rattle can

self-etching primer to spray the outside of the two W-917 tubes. |

2.0 |

| 3/24/07 | I cut the W-918 aileron bellcrank to aileron

pushrod ~27". I am going to have the ends welded as

opposed to riveting. There have been reports of the rivets

"catching" on the edge of the hole where the pushrod passes

through the rear wing spar and I don't want to enlarge the hole.

I sanded the ends where they will be welded to remove the powder

coating. Back to the flaps. I removed the weights from the flap and

removed the clecos in the trailing edge. It was soon

apparent that two days was insufficient for the ProSeal to

adequately cure and bond the trailing edge. I had to get

creative in order to hold it all together long enough to insert

the rivets in the top and tape them in place for back-riveting. I flipped the flap top-side down and used my heavy angle as a

back-riveting plate. I used 3/16" foam sheets as a leveler

for the rest of the flap. I half-shot the rivets and

flipped the flap over. I used the mushroom set to finish

the riveting. I again used -3.5 rivets instead of -3

rivets called out in the Plans in order to get a sufficient shop

head. The left flap is done and perfectly straight! I started again on the assembly of the right flap by drilling

the leading edge skin to 7/64" and blind riveted all but the

outside edges where I squeezed solid rivets. I then shot

the majority of leading edge skin to top skin to spar rivets.

Here, again, I prefer to use -4 rivets as opposed to the -3.5

rivets called out in the Plans in order to get a sufficient shop

head. |

5.0 |

| 3/25/07 | Finished shooting the leading edge skin to top

skin to spar rivets. Riveted the top skin to ribs.

After flipping the flap over and "clamping" the top skin to the

table I riveted the majority of leading edge to bottom skin to

spar rivets. This clamping technique holds the flap

perfectly flat to the table and allows moderately

unobstructed access to the spar for bucking. The word

for today is "tedious".  |

2.0 |

| 3/26/07 | Finished riveting the leading edge to bottom

skin to spar rivets. Installed the blind rivets in the

bottom skin to ribs and squeezed solid rivets in the end rib.

I wasn't happy with the way the ProSeal worked on the trailing

edge on the left flap so I decided to use T-88 on this one.

I've been really happy with how well the T-88 bonded the

trailing edges on the rudder, elevators and ailerons.

Ron Russ gave me a good tip on how to heat the T-88 in a pan

of hot water to make it "soften" and flow more easily. I

put clecos in every hole of the trailing edge. Now to let

the trailing edge set up. |

2.0 |

| 3/27/07 | Tonight I removed the clecos in the trailing

edge and taped in the -3.5 rivets on the topside. After

flipping the flap topside-down, I half-shot the rivets and

flipped the flap over. I used the mushroom set to finish

the riveting. I again used -3.5 rivets instead of -3

rivets called out in the Plans in order to get a sufficient shop

head. The right flap is done and perfectly straight! |

2.0 |

|

Total Hours Flaps |

57.5 | |

| Bellcranks and Pushrods | ||

| 3/28/07 | Laid out a design to drill the rivets

equidistant. Marked the pushrods and drilled the holes to

#30. Deburred the holes and inserted the pushrod ends.

Match-drilled the pushrod ends and inserted the blind rivets.   |

1.0 |

| 3/30/07 | Installed pushrods to aileron bell cranks.

Installed flaps and ailerons to wings.  Pulled the Van's

corrugated conduit through the right wing. This proved to

be quite a task and took me almost 30 minutes for just one

wing...I will pull the left wing later. |

2.0 |

| 3/31/07 | Today I took my bell crank to aileron rods and

rod ends to a local welder. I am really pleased how they

turned out. For those who are interested, the rods are

4130 steel and the rod ends are alloy steel. They can be

welded nicely with a MIG welder using stainless steel wire on

about 30 amps heat. I then ground down the welds and

primed.

I went ahead and bolted the alignment tool to the end rib on

each wing and clamped the ailerons in the neutral position.

I adjusted the rod-end bearings and bolted temporarily. I

had read where some builders are using delrin rod on the bolt as

a rudder stop and I did the same. Unfortunately, I was

following the advice of other builders on the VAF Forum and

mistakenly used 1/2" delrin rod. The result (as shown

below) shows the 1/2" rod diameter is too small to hit the

aileron bracket. After re-reading the Forum it appears the

-9 requires a .75" diameter rod. Oh well, another order

has been placed to ACS... I am a little baffled how to install the washer on this

aileron hinge...It is supposed to go to the right of the bracket

in the "gap" before the hinge. I am embarrassed

to say how much time I have spent trying to figure it out.

I shot an email out to another -9 builder to see what others

have done.

UPDATE: Fellow builder, Bill Repucci, recommended

some thin-walled washer wrenches specially designed for this

purpose so I placed an order to

Avery Tools. |

4.0 |

| Riveting Wing Bottom Skins | ||

| 10/13/07 | Before I can install and fit the wings to the

fuselage I need to finish riveting the bottom skins. I had

already installed the Gretz pitot mount but still need to finish

the plumbing and electrical runs. Since I have conduit

installed, I am good to go. I can install the wingtips

well after I fit the wings so that task will wait as well as

running the wires and antenna cable.

I also wanted to help secure the flex conduit in the ribs so I

applied a bead of clear RTV silicone at several ribs. I began by dimpling and

riveting platenuts on the inspection panel covers. |

2.0 |

| 10/14/07 | Gretz Pitot

Install I had to grind the Gretz pitot in order for it

to fit inside the mount tube. I also had to fabricate a

bracket to mount the Gretz electronic control module. The

pitot is designed to work with the ECM but the wires from the

pitot are only about 18" long. The wires must connect to

the ECM as well as the power and ground. I need to install

the ECM one bay out from the pitot tube in order to have access

to it via an inspection hole. I

riveted the ECM bracket in the adjoining bay with the bellcrank.

I decided to apply a piece of heat shrink tubing over the wires

coming out of the pitot tube to help protect them when routed

through the rib and around the bellcrank. |

2.0 |

| 11/4/07 | I had to wait to install the pitot tube until I

had riveted the bottom skin on the left wing. I connected

the pitot tube to .250 OD plastic tubing with a piece of tubing

which was .250 ID. Finally, I safety wired the tubing

connection. |

|

| 10/28/07 |

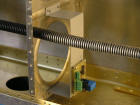

Wing Wiring I am trying to arrange a date for fellow builder (now flyer), Bill Repucci, to fly over from Charlotte, NC to guide me through fitting and drilling the wings to the fuselage. There is a possibility of him coming next weekend so I need to get busy. Before I can close up the bottom skins I need to pull the wiring and cables through the conduit. I am wanting to avoid any wing root wire connectors so I am

leaving 12 feet of wire "pigtails" for routing through the

fuselage once the wings are permanently attached. I am adding LED lights at each inspection panel for light

when I pre-flight after dark. I will tie into a 22ga, +12v

wire where you see the loops. Here you can see how I have bundled the excess and stuffed it

in the lightening holes. |

4.0 |

| 11/2/07 | I received my order for additional RG-400 coax

from SteinAir for the Marker Beacon

antenna in the left wingtip and pulled it through the flexible

conduit. Next, I finished labeling the wires running

through the left wing. I printed labels and after cutting

them out, I covered with clear shrink tube and sealed with my

heat gun. |

1.0 |

| 11/3/07 | While waiting for my riveting partner to arrive

I attended to several odd tasks. I had never riveted the

platenuts to the inspection panels on the left wing. I

also drilled a .250" hole in each inspection panel for

installing LED lights. Riveting Bottom Wing Skins...Finally! Terry arrived late afternoon and we got busy riveting the bottom skin

on the right wing. I decided that since the wings are

already stable in their wing stands it made sense to rivet them

there. This is a task that will take much longer than you

realize. Four and a half hours later we finished.

One more wing to go... |

6.0 |

| 11/4/07 | Today Ben Bierbaum

came up to help me finish riveting the bottom skin on the left

wing. This was a tedious process due primarily to having

to work around the pitot installation.

The only problem was when I dropped the bucking bar down into

the leading edge at the third outside bay... too far to reach.

Now I will need to figure out a way to get it out. |

8.0 |

|

HID Wingtip Light Install |

||

| 3/15/08 | If you have been following my search for

suitable HID lights in my R&D section

you would know that after several months of testing and

searching for the right configuration of lamps, bulbs and light

design I am pleased to say that I have found a light that meets

all of my design requirements. Thanks to the great guys at

HIDFoglight, Ed

and Aram, for their tireless searching and sending me samples to

test. I installed the lamps in less than 6 hours from start to

finish. The first step is to remove the lens section from

the lamp by unscrewing the gray shroud. Next,

remove the "half-moon" shaped plate.

The glass lens is sealed with an "O" ring and secured with four

screws.

One thing that shows the quality of these lamps is the foam

gasket where the lens attaches. The front of these lamps

are water tight. You can now re-install the lens and set aside. Next you will

need to trim the attach plate for your wingtip style. My

installation is in an RV-9A which has a molded fiberglass

"notch" designed in the forward edge. As you can see, the

attach plate needs to be trimmed in order to fit inside the

wingtip.

I placed the attach plate outside the wingtip and marked where

the trim cuts need to be made. I used a Dremel tool with

fiber cut-off discs to cut the thick steel attach plates.

I found that I could cut about halfway through the plate and

then bend and break off the cut section.

Each plate required three trimmed areas. Here you can see

the first attach plate after trimming and deburring as compared

to an original plate.

You can use the first trimmed plate as a template and mark the

second attach plate for trimming. (This is if you want to

install a second light in the opposite wingtip). When you

are done, the plates should look like this. Prepping the Wingtips

Next, I measured out where the attach plate screws would be

drilled as well as the 3" hole for the light in the wingtip.

Ignore the markings on the vertical section as these will be for

the nav/strobe lights.

The hole for the lamp is cut at 3.0 inches using a 3.0" hole

saw. The HID lights generate quite a bit of heat so I

over-sized the cut in the fiberglass to allow adequate clearance

from the lamp. After the lights are installed I will be

attaching an aluminum dress plate which will have a 2.75"

diameter hole.

Next, I had to trim the lamp attach plate in order for the lamp

to clear the inside of the wingtip. The lamp attach plates

attach to the lamp with four screws. After removing the

plate I trimmed one edge and deburred and reattached to the

lamp.

Next, install the three mounting lugs to the attach plate.

There are two "fixed" length lugs and one adjustable lug.

The lugs attach with "twist and lock" plastic nuts.

These lamps are designed to mount either in front of the attach

plate or behind it. I prefer to mount the lamps behind the

attach plate which places the entire lamp within the wingtip.

Next, you install the attach plate (with lugs) to the lamp

assembly. The white nuts fit through the holes in the Lamp

attach flange and the small white caps simply snap on the nuts. Installing the lamps In

order to achieve the proper stand-off from the wingtip I cut

three spacers from 1/4" aluminum tubing. Two of the

spacers are 1.0" and one is 0.25". I also ground a slight

bevel on one end of the spacers to match the angle of the

wingtip. To install the lamps I used the following parts:

Make sure to install the lamp so it is oriented "top up"

after the wingtip is installed on the wing. The lamps

have stamping to indicate the top side of the lamp. A

nice feature of these lamps is the adjustment screw which

allows you to "aim" the lamp for optimum light dispersion.

For example, you will want the landing light to aim directly

ahead while the taxi light would need to be aimed downward. Now, all that is left is to install the outer dress plate.

I will be attaching the 50-watt ballast to the outer wing

rib. HIDFoglight.com

will be offering these lamps to RV builders who wish to have

the finest in wingtip HID lighting. They will soon

also offer another HID lamp for those with the old Duckworks

halogen lamps. It will also be 50-watts and offer a

true retro-fit for the leading-edge lamps. (More info

on the leading-edge HID lamps will be available on their

website. Final pricing on the wingtip HID lights is

available on their website as well. If you would like

additional information on the installation of the wingtip

lights, please feel free to contact me

here. |

10.0 |

|

Wingtip Hinge Installation

|

||

| 1/18/09 |

I am following another tip from builder,

Mark Phillips, who came up with the idea of installing

the wingtips using hinges rather than screws. This allows

you to remove a wingtip in as little as one minute as opposed to

20 minutes removing screws. Also, you don't see those

nasty screws in the tips. |

6.0 |

| 1/20/09 |

Tonight I finished drilling the hinges and spacers to the L & R

wing tips and deburred. I also countersunk the spacers for

the wing tip dimples. |

1.0 |

| 1/23/09 |

I fabbed some AL pieces which will be guides to hold the tip in

place as I later drill to the hinge. I then spent a lot of

time trimming the tip to ensure a good edge where the tip meets

the wing and to make it as clean as possible.

I then drilled the tip to the hinge using 1.25" rivet spacing. |

5.0 |

| 1/24/09 |

I repeated the steps for the right tip and epoxied and riveted

the left tip hinges. I ran out of

West System 206 hardener so I will epoxy the right tip

hinges in a few days. I also had to order some UHMW block

for the hinge pin retaining block. |

5.0 |

| 2/8/09 |

I bonded and riveted the right wingtip upper hinge. I

bonded the Archer Marker Beacon antenna in the left tip and

started bonding the APRS antenna in the right tip. |

2.0 |

| 2/22/09 |

I have been working on the wing tips off and on between other

tasks but have been able to install the tip ribs. I had to

drill the flange in the lateral ribs and use a back light in

order to drill them to the tips. This worked great.

I also glassed in the APRS antenna in the right wing tip. I fabricated and drilled the hinge pin retainer blocks and

test installed them. I need to order some proper Molex connectors for the

navigation lights so I jumped ahead and started trimming the

lens covers using my Dremel tool with a cut-off wheel. |

4.0 |

| 3/7/09 |

Finished the wingtips! I will be installing the light trim

covers once flight testing confirms the proper alignment. |

2.0 |

|

Total Hours this Page |

||

|

Total Hours Wings |

||

| Next: Fuselage |

Copyright ©2005-2009

Hosted by NTI Networks