Home

Shop

Tools

Empennage

Wings

Wings 2

Fuselage

Fuselage 2

Longerons

Aft Fuse Assembly

Center Fuselage

Assembling Center Sect.

Joining Rear & Center

Fuselage 3

Fuselage 4

Fuselage 5

Fuselage 6

Panel

Firewall Forward

Canopy

Wiring

Miscellaneous

Fuselage 2

|

Date |

Description of Task | Hours |

| Longerons | ||

| 5/5/07 | I bought these 4 sawhorses from

Ron Russ for

$20. He used them when building his fuselage. They

should know what to do. Began working on the longerons by marking the

critical dimensions on the right longeron and cutting to final

length (173 7/16"). I put the

drawing with the longeron curve on the floor to use for

comparison. I cut the notch in the aft end as well as the

groove. Bending was a true learning experience...Bend by "whacking" with a

rubber mallet with the angle in the vise to a rough estimation

and lay down on the floor to compare to the drawing...Bend some

more and lay down on the floor...Over and over again. No

matter what you do, you WILL get some vertical deformity.

I ended up just using my hands and working the angle until it

was relatively flat. Another thing I did that helped me

was to number each inch in the bend area. This allowed me

to know what area I needed to either "bend more" or "straighten

out" when I checked it against the drawing. After about

30-40 iterations I felt it was as close as possible (within

1/16" throughout the bend). I clamped up the left longeron, cut to length and cut the notch and

groove in the aft end. I marked off the critical

dimensions and began bending. |

3.0 |

| 5/6/07 | I finished bending the left longeron and

drilled the F-721B aft canopy decks. Lynne stopped in to

check out the fit. |

1.5 |

| 5/7/07 | Finished the longerons by bending the angle

down at the point indicated in the plans. I used my 36"

rule with a small ruler taped to it as a make-shift gauge.

This worked extremely well.  |

.5 |

| Aft Fuselage Assembly | ||

| 5/6/07 | I clecoed the F-779 tailcone skin to the F-711

and F-712 bulkheads. The tailcone skin is pretty thick and

has to be finessed in order to make fit.

Next, I set up three saw horses and clecoed the F-706, F-707 and

F-708 bulkheads as well as the tailcone assembly and F-710 to

the F-778 aft bottom skin. |

1.5 |

| 5/7/07 | Tonight I started to trim the J-Channels and

discovered that Van's had shipped me the wrong length.

Until I receive the correct channels, I will jump ahead and work

on the Center Section. |

.5 |

| 5/22/07 | I got my replacement J-channels yesterday and I

went ahead and trimmed the ends per the plans. I set them

in the channels of the F-707 & F-708 and temporarily clecoed on

the side skins. |

1.5 |

| 5/30/07 | I finished clecoing the side skins to the aft

section bulkheads and bottom skin. I then clecoed on the

tail section. Finally, I used the digital level to check

the fuselage at the F-706 forward bulkhead and shimmed until it

was level. Then, I checked the fuselage at the F-710

bulkhead and I found the fuselage to have a twist of 0.6º

or 1/8 inch in 12 inches. The plans offer nothing

as to how to address this twist but stipulates the twist must be

removed before match drilling or the plane will fly like a

corkscrew through the air (just kidding). I will research

this and call it a night. |

2.0 |

| 5/31/07 | After searching the archives of

Matronics and

VAF as well as consulting fellow builders Bill Repucci and

Mark Phillips, I decided to level the forward end of the

fuselage and clamp to the sawhorse. Then, I "racked" the

tailcone against the twist and checked the amount of twist until

it was showing level. All in all it was relatively simple.

Next, I drilled the four lower J-channels by drilling and

clecoing every fifth hole. I drilled and clecoed fore to

aft, left bottom, right bottom, right middle then left middle.

Next, I drilled between each hole and clecoed following the same

regiment. Lynne wanted to go for a walk so I will finish

tomorrow. |

1.0 |

| 6/1/07 | Tonight I finished drilling the J-channels and

began match drilling the skins.

ELT/Strobe Brackets- Some time ago I ordered the ELT

and Strobe brackets from Vans. By installing the strobe on

the right fuselage wall and the ELT on the left wall I will

essentially free up the floor and these brackets will allow easy

access in the future. Because of the way they attach to

the J-channels, it will be much easier to drill them now and

rivet when riveting the aft section. I pulled out my strobe power supply and laid out the holes.

After drilling to #19, I then used my #8 platenut jig and

drilled for the rivets. After deburring and dimpling, I set aside. I don't have

my ELT yet so I will install the pre-drilled platenuts and hope

the hole pattern matches. However, since the brackets

attach to the J-channels with pulled rivets, I could rivet at

any time in the future (as long as I already have the doles

drilled). |

3.0 |

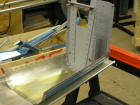

| 6/2/07 | Finished match-drilling the aft fuselage and

took these pics before disassembling for deburring and dimpling.

After removing the side skins I was able to drill the ELT/Strobe

brackets to #30. Removed the plastic along the rivet lines. I deburred

the bottom skin and dimpled and deburred the left side skin.

|

7.0 |

| 6/3/07 | Finished deburring skins and bulkheads.

Dimpled skins and bulkheads. Scuffed and washed skins.

Alodined and primed ELT/Strobe brackets. |

3.0 |

| 6/4/07 | Deburred the J-channels. Riveted the

platenuts to the ELT/Strobe brackets. |

1.0 |

| 6/5/07 | Finished deburring, scuffing and washing the

J-channels. SanChem treated the tail skin. |

1.0 |

| 6/7/07 | SanChem treated the inside bottom skin, inside

the side skins of the aft fuselage and the J-channels. |

2.0 |

| 6/8/07 | We have been having such great weather and

since things are slow at work I decided to take the day off for

RV building ;) I assembled and riveted the F-711 and F-712

bulkheads to the F-779 tailcone skin and dimpled the J-channels. I had been warned that later when I will be installing the

longerons that they will not fit in the slots punched in the aft

bulkheads. I went ahead and opened these slots with

the Dremel tool. I then assembled the aft fuselage and back-riveted the side

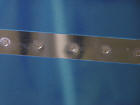

skins to the bulkheads and J-channel stiffeners. I took a

couple of shots to show the difference of how the rivets appear

when riveted versus back-riveting. The first shot is a

line of rivets after riveting and the second shot is a line that

was back-riveted. This is a really tedious job, especially with the June heat

warming the shop to a toasty 85 degrees. The tough thing

here is that all the J-channel rivets are oriented such that you

cannot "see" the rivet because it is blocked by the channel.

This is referred to as "blind riveting". All in all it

went well with only two "slips" where I didn't have the

back-riveting holder on the rivet resulting in a slight skin

dent. Actually, it is an "outie". I will need help riveting the bottom skin and will wait until

Jim Olson can come over on Monday

evening. |

7.0 |

| 6/10/07 | Today we got a visit from my flying buddy,

Ben

Bierbaum as he and his son and a couple of friends were on their

way to Boy Scout Camp. They thought the plane was "cool". After lunch, Jim Olson arrived and we went to town back-riveting the aft fuselage and center section bottom skin. On to the Center Section... |

2.5 |

| Center Section | ||

| 5/11/07 | I bought some 7/16" x 4" bolts for temporarily

attaching the F-904 bulkhead. I chucked the bolts in my

drill press and sanded them down a couple thousands of an inch

so they should slide in nicely. Began by cutting the F-916C spacers. I then cut the section out

of the F-916L & F-916R seat ribs as well as trimming the seat

access ribs. I used a unibit and enlarged the tooling hole

on each seat rib to 5/8" for electrical wiring runs. I

deburred the seat ribs and dimpled for the platenuts. I

then installed the platenuts. |

4.0 |

| 5/12/07 | I sorted out the seat ribs and clecoed them to

the aft section of the F-904 Spar bulkhead. I then clecoed

the seat ribs to the F-705 bulkhead. I then clecoed the

baggage section ribs to the F-705 bulkhead. I inserted the

F-916C spacers and drilled the 1 1/2" holes in the baggage ribs

for the steps using the fly-cutter.

Next, I flipped the assembly over and clecoed the F-776 bottom

skin to the center section. The trick to getting the holes

to match up is to start clecoing along the flange of the F-705

and then move fore and aft clecoing as you go. I then

flipped the assembly over again and drilled the F-623 L&R.

I used my soldering iron to remove the plastic along the rivet

lines. I also had to fabricate the F-623A-FWD and F-623A-AFT

attachment straps in order to install the F-623 side pieces.

When I match-drilled the F-623, I was not happy with the edge

distance I got on the F-623A-FWD straps so I fabricated new

straps. The original straps are on the bottom in the photo

and the new-and-improved straps are on top. These

are much better. I then bolted on the forward half of the F-904 Spar bulkhead

and clecoed to the bottom skin. Finally, I match-drilled

the bottom skin to the entire Center Section as well as to the

F-904 flanges. I also drilled the F-904H Center Section

Side Plates to the F-904 and clecoed. |

8.0 |

| 5/13/07 | I was reminded by

Mike Behnke of an article on Van's

website that discusses the span wise rows of rivets across

the forward F-904 bulkhead. This area of the skin will be

overlapped by the forward F-972 bottom skin and the rivet holes

will need to be countersunk as opposed to dimpling. I removed F-976 bottom skin and deburred the holes and edges. I

then started dimpling the bottom skin. Lastly, I started match-drilling the ribs to the Center

Section bulkheads. |

4.0 |

| 5/14/07 | Finished dimpling the F-976 bottom skin.

There are about 12 holes you cannot reach with the C-Frame

dimpler so I used the pop-rivet dimpler and it went fine. |

1.0 |

| 5/15/07 | Match-drilled the baggage section ribs to the

F-705 bulkhead. Deburred the baggage ribs and the F-904H

Center Section Side Plates. |

1.0 |

| 5/18/07 | Dimpled the baggage ribs and the F-623A-FWD and

F-623A-AFT attachment straps. Disassembled and deburred the

center section side plates and the seat ribs. |

2.0 |

| 5/19/07 | Dimpled the seat ribs. Began prepping the center section ribs for

priming by scuffing and washing with soapy water. Also

scuffed and washed the bottom wing skins. Unfortunately,

the priming session was cut short when my water stopped

flowing...Apparently my submersible pump 245 feet down in my

well went Tango Uniform. When my Pump and Well repairman

finally got here we pulled the pump and replaced. By

7:30pm we had water again but I was too pooped to work anymore

on the plane. |

3.0 |

| 5/20/07 | Continued priming of center section ribs and

bottom skin. My refined process now is to (1) scuff with

soapy water, rinse and let air dry. (2) Brush the part

with AlumiPrep, rinse with water and air dry. (3) Brush

the part with SanChem Part "C", rinse with water and let air

dry. And then (4) brush the part with SanChem Part "A" & "B",

rinse with water and let air dry. It seems like a tedious

process, (and it is) but you get a nice even chemical conversion

to the alclad and it adds no weight.

For the smaller parts such as the small spacers and attach straps I scuff with soapy water, immerse in AlumiPrep for a couple of minutes, rinse with water, then immerse in Alodine for two (2) minutes, rinse with water and let air dry. Finally, I shoot the small parts with a thin coat or self-etch primer. This is such a boring detail that takes so much time, I am

not taking any photos. |

2.0 |

| 5/21/07 | I decided to prime the ribs with the Nason

epoxy primer instead of the Sanchem since I wanted to get this

done and I could spray all the parts in about an hour. I

must admit that although quicker, it was much messier to clean

the spray gun and I gained a few ounces of weight. The

Nason is a good product and will give me excellent corrosion

protection. |

2.0 |

| Assembling the Center Section | ||

| 6/8/07 | Began the final assembly by clecoing the seat

ribs to the aft F-904 Spar bulkhead. I installed the upper

and lower AN3 bolts through the ribs and bulkhead and torqued to

25 in/lbs. |

1.0 |

| 6/9/07 | Riveted the seat ribs to the aft F-904

bulkhead. Riveted the seat ribs and the baggage floor ribs

to the F-705 bulkhead. Like others have mentioned, this is

difficult to rivet and do a good job because the access is so

poor.

I flipped the center section over and clecoed on the bottom

skin. I also match-drilled the F-915 outside seat ribs

using the centerline I drew on the rib flanges previously. I got a call from Jim Olson this

evening and he is coming over tomorrow so we should be able to

finish all the skin riveting. I went ahead and pop-riveted

the ELT/Strobe brackets as well as drilling and installing the

really cool static ports I got from fellow RV builder

Mark Phillips at the Possum Works

in Tennessee. |

6.0 |

| 6/10/07 | Today Jim Olson came over to help me rivet the

aft fuselage as well as the center section bottom skin.

All went well and we finished by flipping the center section and

clecoing the seat pans and baggage floors. One question I have for other builders is how they trimmed

the F-623 L&R corner ribs. I also wonder about the 1/4" bolts that connect the fore and

aft spar bulkhead. Here you can see that even with the

correct length spacer, the bolt appears too long. |

2.5 |

| 6/11/07 | I match-drilled the seat pans and baggage

floors. I also drilled the F-915 outer seat ribs to the

seat pans being sure to allow 3/32" gap for clearance with the

side skins. |

1.0 |

| Joining the Rear and Center Fuselage Assemblies | ||

| 6/12/07 | This evening Lynne and I flipped the center

section and set it carefully on two sawhorses. After

aligning the center section with the aft fuselage and lifting

the tailcone a few inches we were able to get it together enough

to get one cleco set. It was a really tight fit but by

working it across one hole at a time we were able to get it

"zipped" together. |

.5 |

| 6/14/07 | Trimmed the baggage side ribs to the correct

size. Installed the longerons. I had to slightly

enlarge the groove I had cut in the rear for fitting over the

F-712 bulkhead.

I plan to install the side skins soon in order to see how well

my bends turned out. |

1.0 |

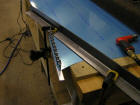

| 6/15/07 | I fitted the side skins just to see how well

the longerons would line up and was pleased to see they appear

in perfect alignment. I'm really glad I was so anal with

measuring when I was bending them now. After jogging the

aft fuselage I was able to get the side skins to align enough to

get clecos installed. I then removed the side skins and

drilled the 1 1/2" holes for the steps.  I re-attached the side skins and marked the flanges of the

baggage side ribs. After removing the ribs I rough cut the

flanges with the bandsaw and cleaned them up with the bench

grinder. Next, I fluted the arm rests and clecoed them to

the side skins. |

2.0 |

| 6/16/07 | I spent most of the day helping our

Electrician who we had come over to wire our basement.

When we built the house 3 1/2 years ago we had left it

unfinished so we are starting with the electrical. After

he left, I snuck out to the shop...

I started by match-drilling the armrests, then removed and

deburred. Removed the left side skin and clamped the skin

to the table. I cut a 12" piece of .125 angle and drilled

and clecoed to the skin. I clamped vise grips to the angle

and made the conical bend in the skin. After the bend was satisfactory, I clecoed the skin to the

fuselage. I clecoed the F-623 baggage side ribs to the

fuselage and clecoed the conical bend. Finally, I installed and clecoed the aft canopy decks to the

longerons. |

3.0 |

| 6/17/07 | Today, I celebrated Father's Day by removing

the right skin and making the conical bend. I then

re-attached it to the fuselage.

Next, I drilled the longerons. I also had to trim the

front ends of both longerons to allow for a .75" clearance back

from the ends of the side skins. |

6.0 |

|

Total Hours this Page |

88.0 | |

|

Total Hours Fuselage (as of 6/14/07) |

153.0 | |

| Next: Forward Fuselage |

Copyright ©2005-09

Hosted by NTI Networks